The connection between PE gas pipe is electrothermal melting. The strength of the joints is higher than the strength of the pipe body; it can be safely used in the temperature range of 60-60°C, so its low temperature embrittlement temperature is extremely low and it is used in winter construction. At the same time, the pipe will not exhibit brittle fracture; HDPE Gas Pipe has low notch sensitivity, high shear strength and excellent scratch resistance, and is also outstanding in resistance to environmental stress cracking.

Hdpe gas pipe buried in the ground will not cause any degradation of the pipeline; because polyethylene is an insulator, it will not rot, rust or electrochemical corrosion; in addition it will not promote the growth of algae, bacteria or fungi, so hdpe The corrosion resistance of the tube is particularly good. It has a long service life and can be used in open outdoor environments for 50 years. It is not damaged by ultraviolet radiation.

HDPE pipes are very easy to bend and can be engineered to bypass obstacles by changing the direction of the pipe. HDPE pipelines have a variety of construction techniques. In addition to the traditional methods of excavation, a variety of new non-excavation techniques such as jacking, directional drilling, liners, and cracking can be used. For some sites that are not allowed to excavate, it is the only choice, so the HDPE pipeline application is more extensive.

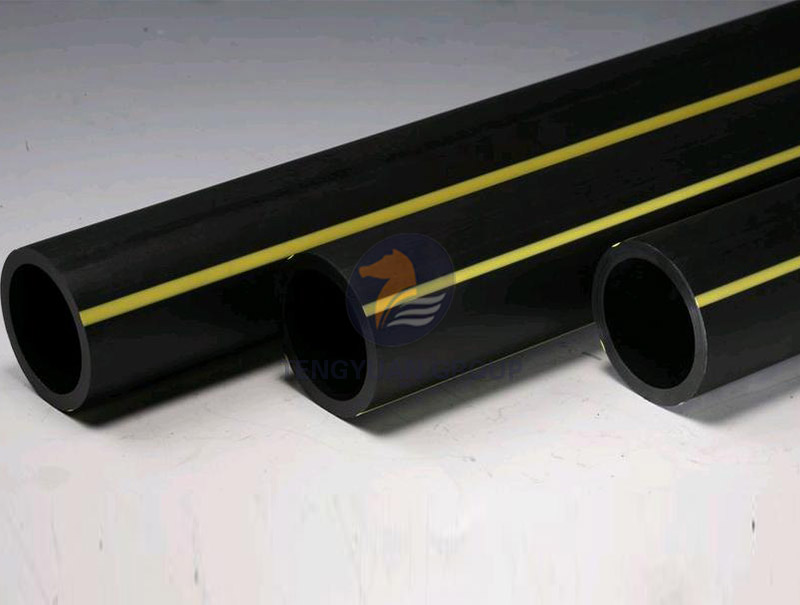

We are a professional HDPE Gas Pipe Manufacturer in China, we also supply HDPE Drainage Pipe and other kinds of pipes, if you need, welcome to contact us.