The pressure test of PE Pipe is a very important link, which is directly related to the use of the product. Therefore, we need to strictly control the PE pipe when testing it. Next, we will introduce some related methods.

After the air in the PE pipe to be tested is excluded, the pressure is increased to the required pressure value at a steady boosting speed, the pressure gauge should be placed it at the lowest point of the pipe.

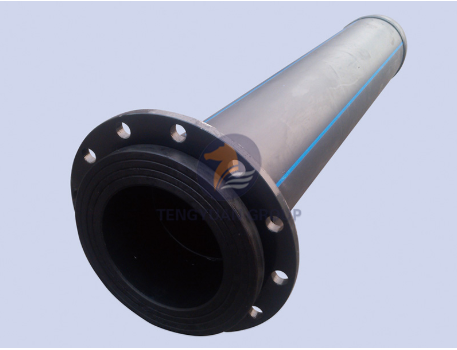

The pressure test can be carried out before or after the pipeline is backfilled. The pipeline should be covered with a certain interval. Especially for the meandering pipeline, the pipeline should be fixed in place during the pressure test. The flange connection should be exposed to facilitate inspection of leaks.

During the pressure test, the pressure drop is caused by the continuous expansion of the pipe. It is normal to produce certain pressure drop during the test, it cannot be proved that the pipe system must leak or break.

We owns anti-static spraying for PE pipe fittings and many other patent technologies. Our products include HDPE Steel Mesh Reinforced Pipe, Dredging Engineering Pipe and other products. If you have any questions, please contact us.